How to Prevent Step Loss for Stepper Motor

Stepper motors operate open loop. When a stepping motor does not operate correctly in a specific situation, the common conclusion is that either the drive electronics or the motor is faulty. The motor selection and the choice of the driver are critical. However, other factors contribute to step losses.

The following points are important to examine for the analysis of step losses or non-operation in a methodical fashion across a variety of applications:

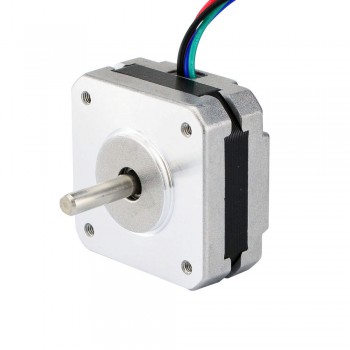

Stepper Motor Selection

Motion profile

Start-Stop operation

Trapezoidal profile

External commutation errors

External events

Back driving

Increase of the pay load over time

Stepper Motor Selection

The first task is to select the right stepper motor for the application. For the wider selection, those basic theoretical rules have to be respected:

Select the hybrid step motor based on the high torque/speed point required by the application (selection based on the worst case)

Use a 30% safety factor from the published torque vs. speed curve (pull-out curve).

Ensure that the application cannot be stalled by external events

It is important to remember that a stepper motor does not operate like a DC motor. There is no working point parameterization, and the phase current does not increase to overcome variations of load. As long as the speed vs. torque requirement of the application is within the specs of the motor, no problem will be encountered. If this requirement is out of the specs, the motor stalls (OK or NOT OK functionality). In any case, the current in the phases is not changing and adapting by itself to the situation.

To read the complete technical paper and learn more about how to prevent step losses and tips for troubleshooting, download the free 4-page pdf now by clicking the button below.

Previous:Linear Stepper Motor Working Principle

Next:The working principle of linear actuator stepping motor