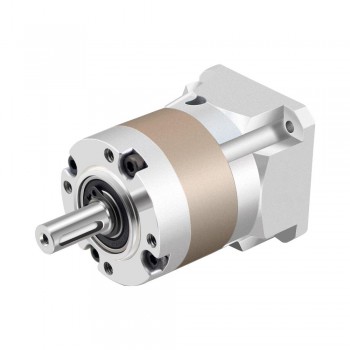

CNC Spindle Motor

A CNC spindle motor is a critical component in computer numerical control (CNC) machines that drives the spindle, which holds the cutting tool or workpiece. The spindle motor provides the rotational power necessary for various machining operations such as cutting, drilling, milling, and engraving. Spindle motors for CNC are electric motors which are compatible with many industrial 3 axis and 5 axis CNC router machines, CNC milling machines and robots. Also CNC spindle motors are widely used in manufacturing factories that are cutting plastics, wood, metal, foam and composites materials.

Water-cooled spindle motors and air-cooled spindle motors are two common cooling methods used in CNC machines. The choice between water-cooled and air-cooled spindle motors depends on factors such as the specific machining requirements, power levels, operating conditions, and budget. Water-cooled spindle motors are often favored for high-power and continuous-duty applications, while air-cooled spindle motors are commonly used for lower power and intermittent machining operations.

The choice between water-cooled and air-cooled spindle motors depends on factors such as the specific machining requirements, power levels, operating conditions, and budget. Water-cooled spindle motors are often favored for high-power and continuous-duty applications, while air-cooled spindle motors are commonly used for lower power and intermittent machining operations. It's important to note that the specific application of CNC spindle motors can vary depending on the industry, machine type, and desired machining operations. CNC spindle motors offer versatility and flexibility, making them suitable for a wide range of machining applications.

Subcategories