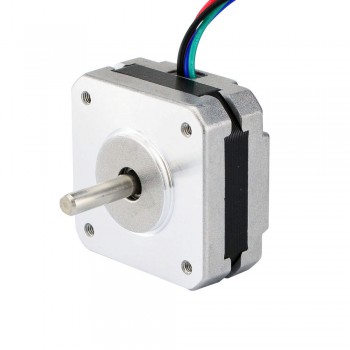

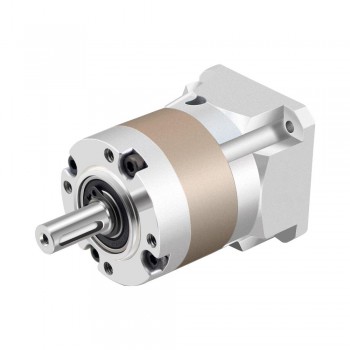

Air Cooled Spindle Motor

CNC Spindle motors are also called high speed motors which have the advantages of fast speed, small size, light weight, low material consumption, low noise, low vibration. It mainly used in wood, aluminum, stone, hardware, glass, PVC and other industries.

Air-cooled c rely on airflow generated by fans or blowers to dissipate heat. The motor has built-in cooling fins or a dedicated cooling system that facilitates the airflow and removes heat from the motor housing. Air-cooled systems are generally easier to maintain compared to water-cooled systems. Regular cleaning of cooling fans and ensuring proper airflow is typically sufficient to maintain their performance.

However, air-cooled spindle motors may generate more noise during operation compared to water-cooled motors. The cooling fans or blowers can contribute to the overall noise level of the CNC machine. Also Air-cooled CNC spindle motors have limitations in handling high heat loads. They are typically used in light to medium-duty machining applications where lower power and intermittent operation are involved.

Water-cooled spindle motors are often favored for high-power and continuous-duty applications, while air-cooled spindle motors are commonly used for lower power and intermittent machining operations. Water-cooled spindle motors are often favored for high-power and continuous-duty applications, while air-cooled spindle motors are commonly used for lower power and intermittent machining operations. You can choose the right spindle motors accourding to your needs.