Servo Motors

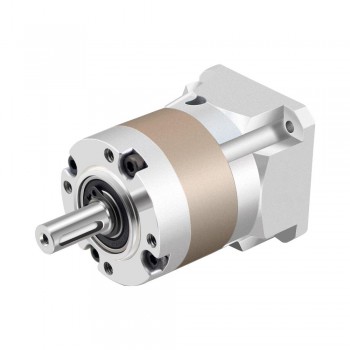

A servo motor is a type of electric motor that can rotate an output shaft at precise angular speeds in response to pulses of input signal. It consists of an electric motor, a feedback device, and a controller. They are able to accommodate complex motion patterns and profiles. Although they are small in size, they can pack a lot of power, and are quite energy efficient. Servo motors for sale online have many advantages that make them widely used in different industries. They are precise and accurate, which makes them suitable for tasks where accuracy is important. Servo motors also have high torque, which is fit for applications that require heavy lifting or pulling.

The main benefit of servo motors is they provide high levels of torque at high speed – something stepper motors can't do. They also operate at 80 – 90% efficiency. Servo motors can work in AC or DC drive, and do not suffer from vibration or resonance issues. Servo motors have many advantages, but a major drawback is that they are more expensive than stepper motors. The servo motor is a small and effective motor and it can be used in some serious applications like precise position control.The controlling of this motor can be done with a PWM (pulse width modulator) signal. The applications of these motors mainly include in industrial robotics, computers, toys, CD/DVD players, etc. These motors are widely used in some applications where a specific task is to be done regularly in an exact manner.

Subcategories