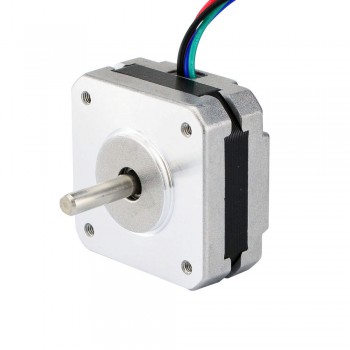

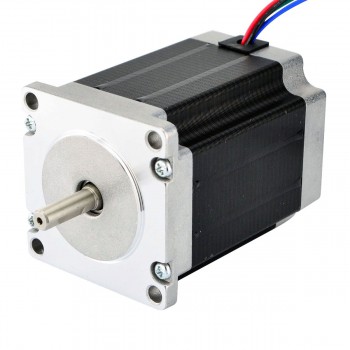

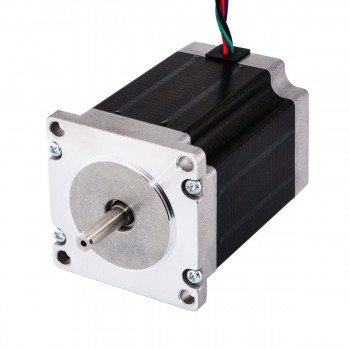

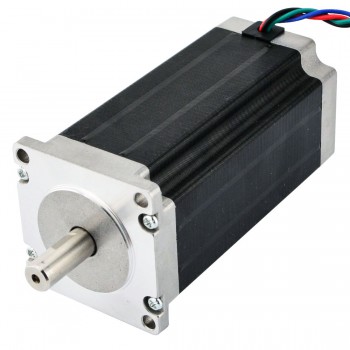

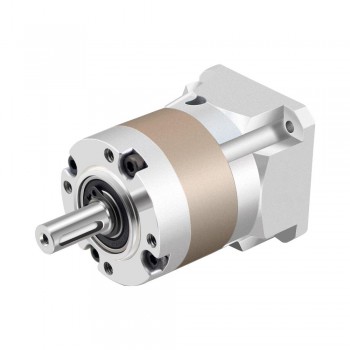

External Linear Stepper Motor

Linear stepper motors actuators are a effective solution when it comes to converting rotary motion to linear, particularly when the application does not require the accuracy of a linear servo motor or closed-loop stepper motor/encoder operation.

These external linear stepper motor actuators use a motor with a hollow shaft and integrate one end of the screw directly into the motor, so the nut remains external to the motor. Like a traditional screw-motor setup, the motor’s rotation causes the screw to turn, which advances the nut (and the load) along the length of the screw shaft. In this design, the opposite end of the screw (not attached to the motor) is unsupported, which is acceptable for light loads and short stroke lengths. However, many applications will require support for the free end of the screw, along with a linear guide to support any radial loads.

The external linear stepper motor actuator can replace the cylinder in some applications, with the advantages of precise positioning, controllable speed and high accuracy. External linear actuators are generally chosen for linear sliding systems with strokes of 60 to 500 mm. However, a long screw can also cause problems, as the actuator and screw resonate at certain positions in the stroke, thus causing noise. The use of drive technology such as subdivision and setting acceleration and deceleration can reduce noise, and the design of the screw end with bearing support can also help to reduce noise.

Contact our application engineers today for more information or guidance in selecting the correct captive, non-captive or external linear actuator for your application.