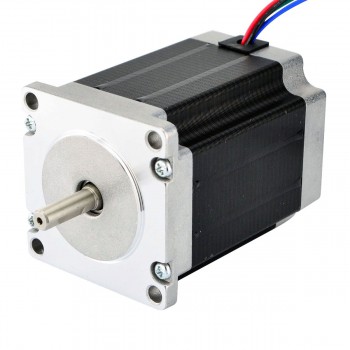

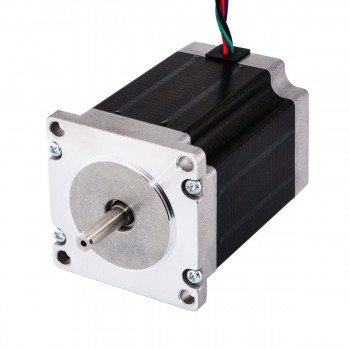

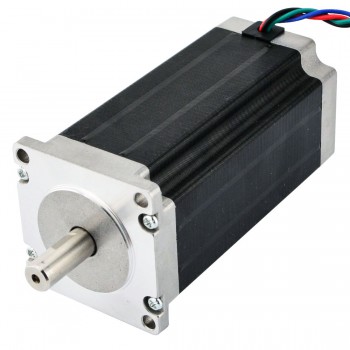

Nema 24 Stepper Motor

The Difference Between a NEMA 23 and NEMA 24 Motor

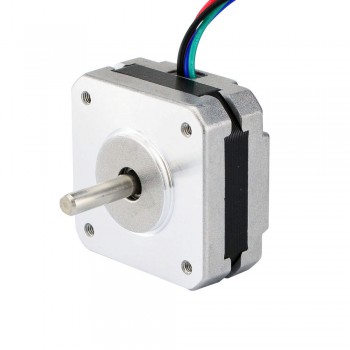

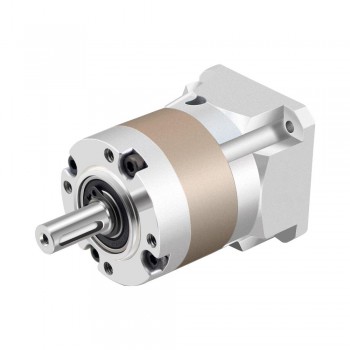

A series of stepper motors with flange 60 x 60mm (also known as NEMA24), slightly larger than the most common NEMA23.The larger internal rotor allows to improve the performance of the application when the load is highly inertial, as it improves the inertia relation between the motor and the load itself.

The frame size difference of the NEMA 23 and 24 is very slight on the motor mount. The bigger difference between these stepping motors is the torque. Make sure that the motor that you purchase has the appropriate torque for the axis that it will move. Is is safe to go with the higher torque? Or if the torque is too high for what i need is that bad? You can use a motor with higher torque. Just make sure to select the correct driver for that motor.Choosing the correct motor for your application can be difficult. If you have any doubts please contact us. We will help you find the suitable motor for your application.