Industrial Applications of Brushless DC Motors

Industrial Applications

For industrial applications, brushless DC motors are primarily used in servo, actuation, positioning, and variable speed applications where precise motion control and stable operation are critical for the satisfactory operation of the manufacturing or industrial process. They are commonly used as:

Linear motors

Servomotors

Actuators for industrial robots

Extruder drive motors

Feed drives for CNC machine tools

Linear Motors

Linear motors produce linear motion6 without the need of a transmission system, such as a ball-and-lead screw, rack-and-pinion, cam, gears or belts, that would be necessary for rotary motors. Transmission systems are known to introduce less responsiveness and reduced accuracy. Direct-drive linear motors do not exhibit these shortcomings.

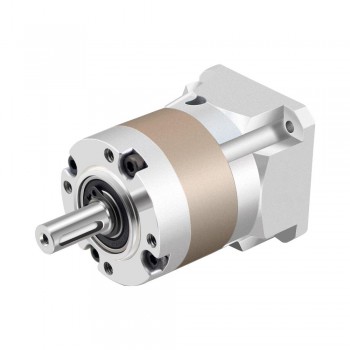

Servomotors

Servomotors are used for mechanical displacement, positioning or precision motion control based upon an input control and output feedback signal that establishes a tightly controlled, stable, closed loop operation. Servomotor drives are commonly used in machine tool servos, robotic actuator drives, among others.

Actuators for industrial robots

Permanent magnet DC motors12 primarily function as the actuators to move the joints of industrial robots for pick-and-place or tool positioning in assembly, welding and painting operations. (It merits noting that when heavy payloads are involved, hydraulic motors are typically used.13) BLDC motors are preferred over brushed motors in robotic applications due to their compact size, power density, and maintenance-free characteristics.

Extruder drive motors

The function of the extruder drive & motor is to provide energy to turn the screw that compresses the polymer. 14 DC drives are the popular extruder drive due to their low cost and versatility. Since variations in screw speed can change the dimensions of the final extruded product, a precision motion control system is required to ensure product quality.

Feed drives for CNC machine tools

There are two drives used in CNC machine tools: spindle and feed drives.17 Spindle drives provide the motion and power for drilling, milling or grinding operation while feed drives function as axis drive motors and essentially replace the “manual hand wheel controls used in conventional machine tools.

Previous:A Brief Introduction to the Working of Stepper Motor Actuators

Next:FAQ of Linear Stepper Motor Basics