Servo Motor vs Stepper Motor: Which is right for your application?

Servo Motor vs Stepper Motor: Which is right for your application?

Stepper Motors

Stepper motors consist of a rotor with permanent magnets and a stationary stator that carries the windings. When current runs through the stator windings, it generates a magnetic flux distribution that interacts with the magnetic field distribution of the rotor to apply a turning force. Stepper motors feature very high pole counts, typically 50 or more. The stepper motor driver energizes each pole in sequence so that the rotor turns in a series of increments, or steps. Because of the very high pole count, the motion appears to be continuous.

Stepper motors have a number of positive attributes. Because they generate incremental motion, they are generally run open loop, eliminating the cost and complexity of an encoder or resolver. The high pole count allows them to generate very high torque at zero speed. They are compact and generally economical.

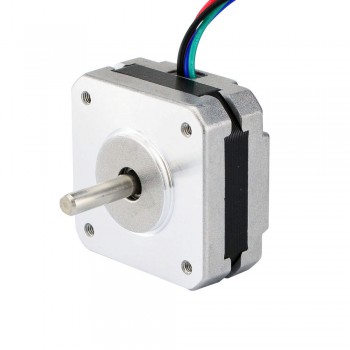

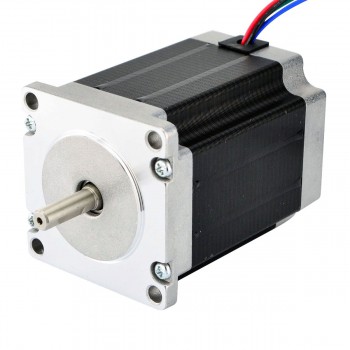

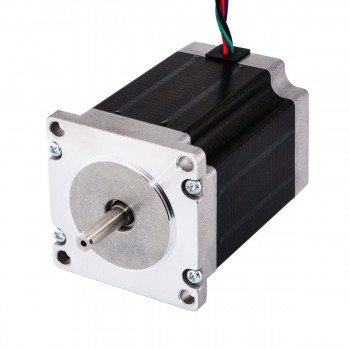

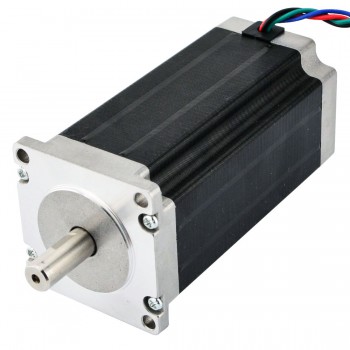

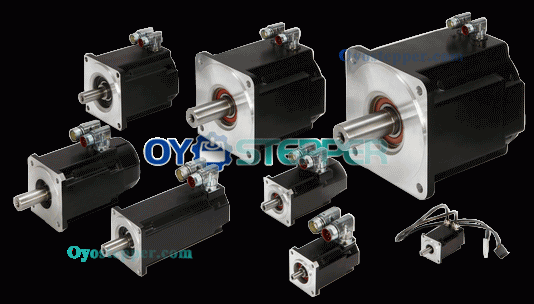

Stepper Motor

Figure 1: Stepper motors deliver stable performance at an economical price point for applications requiring low speed, acceleration, and accuracy. (Courtesy of Kollmorgen)

On the downside, stepper motors have speed limitations. They generally run at a speed at 1200 RPM or lower. Although they generate high torque at zero speed, torque falls off as speed increases (see figure 2). A motor that generates 100 ounce inches at zero speed might only deliver 50 ounce inches at 500 RPM, for example, and just 10 ounce inches at 1000 RPM. In theory, a gearbox could be used to increase torque, but this is where the low speed of stepper motors becomes a problem. Adding a 10:1 gear reducer to a 1200 RPM stepper motor might boost the torque by an order of magnitude but it will also drop the speed to 120 RPM. If the motor is being used to drive a ball-screw actuator or similar, it probably will not deliver sufficient speed to satisfy the needs of the application.

Stepper motors generally are not available in frame sizes larger than NEMA 34, with most applications falling in the NEMA 17 stepper motor or NEMA 23 stepper motor sizes. As a result, it is unusual to find stepper motors capable of producing more than 1000 to 2000 ounce inches of torque.

Stepper motors also have performance limitations. You can think of a stepper motor as a spring-mass system. The motor needs to break friction to begin turning and move the load, at which point the rotor is not fully controlled. As a result, a command to advance by five steps may only result in the motor turning four steps – or six. If the drive commands a motor to advance 200 steps, however, it will do so to within just a few steps, which at that point represents an error of a few percent. Although we command stepper motors with a resolution of typically between 25,000 and 50,000 counts per revolution, because the motor is a spring-mass system under load, our typical resolution is 2000 to 6000 counts per revolution. Still, at these resolutions, even a 200-step move corresponds to a fraction of a degree.

Previous:The Advantages and Disadvantages of Servo Motor