How to choose the appropriate size of a linear actuator?

When selecting the appropriate size of a linear actuator, applying one general number to make a selection, such as a maximum load rating, is difficult.

What questions should you answer when sizing a Linear Actuator?

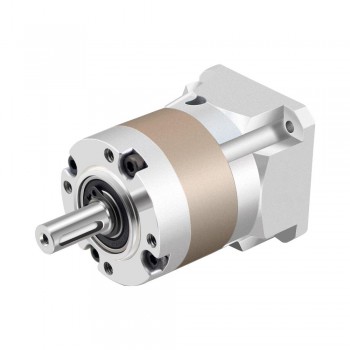

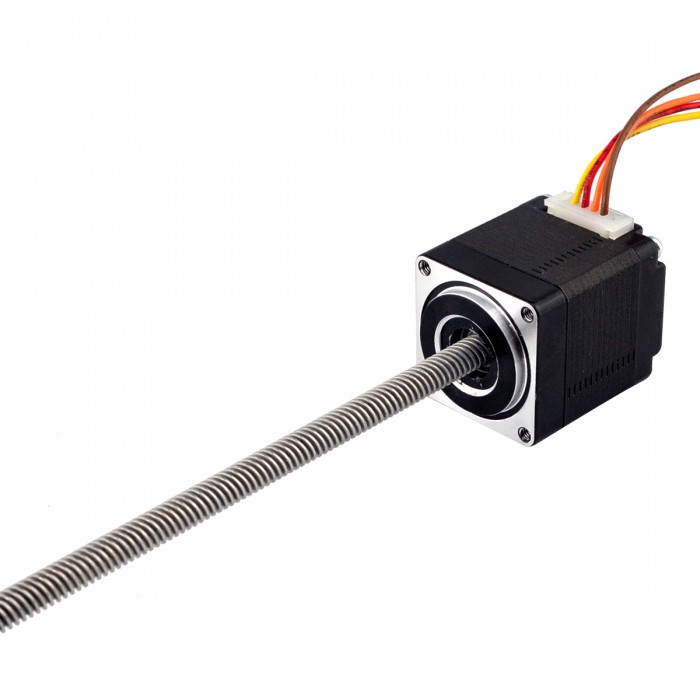

1 - Should the Linear Actuator Be Driven By a Lead Screw or Ball Screw?

Many actuators are built with lead screw or ball screw drive mechanisms. To determine which option is suitable for your application, you must consider load, speed, efficiency, back-drivability, cost, life, and repeatability requirements.

2 - Repeatability vs. Accuracy

Accuracy

Accuracy in a linear actuator refers to point A to point B positional tolerance. For example, when the motor driver signals the actuator to move 1", accuracy is the actual distance moved versus the theoretical difference.

Repeatability

Repeatability measures how close or exact the linear actuator can return to a specific point from either direction of travel. The tolerance is highly dependent on the type of nut and lash (axial clearance) between the nut and lead screw or ball screw.

3 - To Backdrive or Not to Backdrive?

A ball screw typically has a 90% efficiency. The downside of this higher efficiency is back-driving. Backdriving results from the load pushing axial on the screw or nut to create rotary motion. A ball screw will require a brake to keep the system from back driving and maintain its position when the power is off.

4 - Does the Linear Actuator Need Lubrication?

The number one cause of bearing and ball screw failure is lubrication. Insufficient or poor application -- or simply using the wrong lubricant can lead to actuator failure. Outside influences impacting the lubrication, such as contamination, can also lead to degradation of the lubricant.

5 - What Safety Factor Should You Consider?

Most linear actuators have a safety factor built into the design load ratings. Typical safety factors are 1.5 to 2.0, but the required safety factor can be very application-specific.

6 - Cost

All of the previously mentioned considerations directly correlate to the cost of a linear actuator. Review the requirements to determine which are essential for the application and successfully meet each axis's objectives.

7 - Capacity

Is the linear actuator design load rating static or dynamic? If the load is dynamic, does that apply to all speeds? Maybe not. The Pressure-Velocity (PV) may be exceeded if it utilizes a plastic nut.

8 - Stroke Length

Stroke length is often overlooked. Based on the unsupported length, the rotational speed of the lead screw or ball screw should not exceed the critical speed of the shaft. Critical speed is the rotational speed in RPMs that excites the natural frequency of the lead screw.

9 - Operating Environment

When selecting the correct linear actuator for your application, the operating environment is a critical consideration. Harsh conditions, dust, and dirt will severely impact life and can cause the actuator to become inoperable.

10 - Is A Guide Rail Required?

Guide rails for linear actuators can take several forms. Rolling element linear bearings, traditionally called profile rails, are among the most common guidance systems used due to their load carrying capacity and ease of mounting.

These are the steps and considerations for sizing and selecting linear actuators. oyostepper provides a wide range of actuators customizable to fit a specific application or unique requirements. if you have any question on choosing a proper linear actuator motor, please feel free to contact us at oyostepper.com.

Previous:How a Pancake Stepper Motor Works and its Applications

Next:The Disadvantages and Advantages of PM Stepper Motor