The Disadvantages and Advantages of PM Stepper Motor

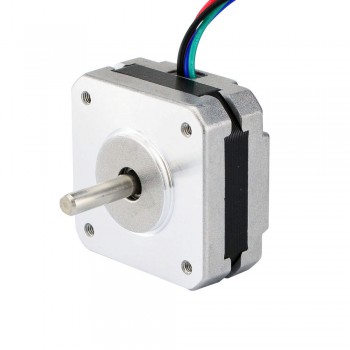

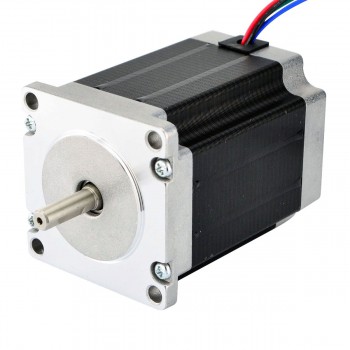

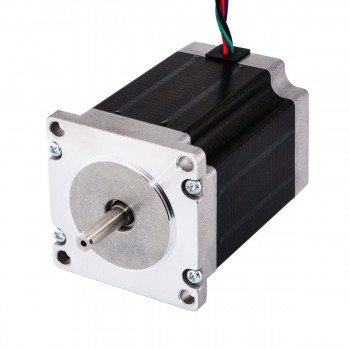

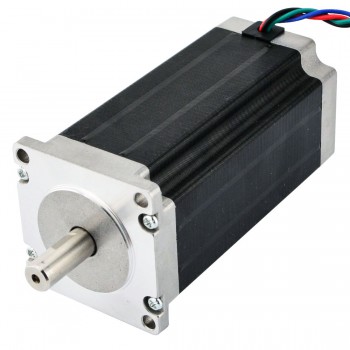

The Permanent Magnet Stepper Motor has a stator construction similar to that of the single stack variable reluctance motor. The rotor consists of permanent magnet poles of high retentivity steel and is cylindrical in shape. The concentrating windings on diametrically opposite poles are connected in series to form a two phase winding on the stator.

A permanent magnet stepper motor is a compatible and highly efficient device that has numerous applications. Since the rotor is made of permanent magnets, it does not need any external excitation which makes it very useful in applications such as toys, small motors, etc. Because of its design aspects, the step-angle of each rotation can be easily designed, which makes it useful in delicate applications such as medical instruments and aeronautical structures. Due to its small size, it is highly mobile and easy to use. This article discusses an overview of the permanent magnet stepper motor.

Advantages and Disadvantages of PM Stepper Motor:

The advantages of a permanent magnet stepper motor are

It is compact and small in size, which makes it useful in many applications

Due to the absence of any external excitation, the losses are less

Due to the absence of any external excitation, the maintenance is less.

It can be connected to the external circuit, to control the speed of the motor

Sensors may be used to locate the rotor windings

Can be operated in a wide range of speed and torque.

The disadvantages of a permanent magnet stepper motor are:

Due to limitations in permanent magnet, it cannot be used for high power applications

Torque produced is limited

The life of a permanent magnet is limited.

Applications:

The applications of a permanent magnet stepper motor are:

Aeronautical industry

Robotics

Toys

Manufacturing

Control industry

Mills and printing

Previous:How to choose the appropriate size of a linear actuator?

Next:The Application of servo motor and how it works