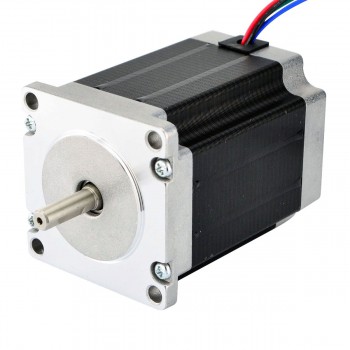

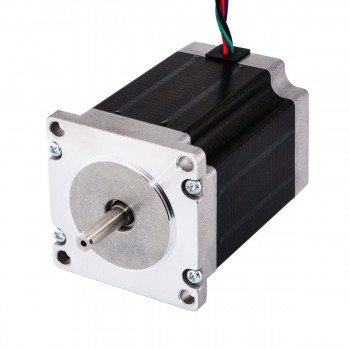

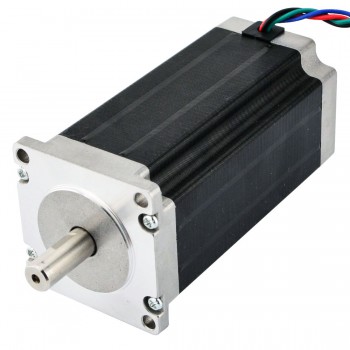

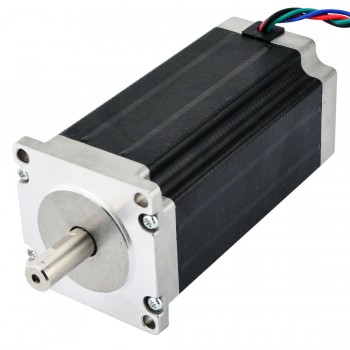

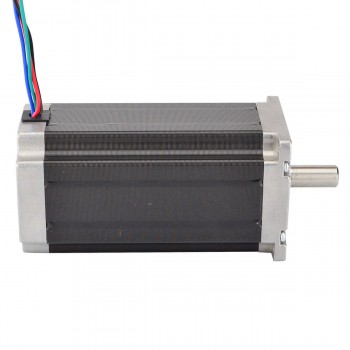

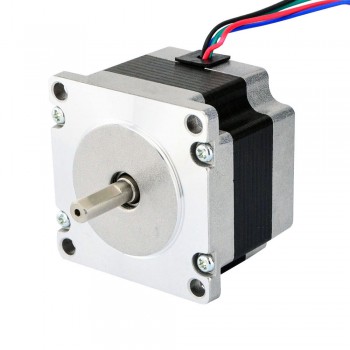

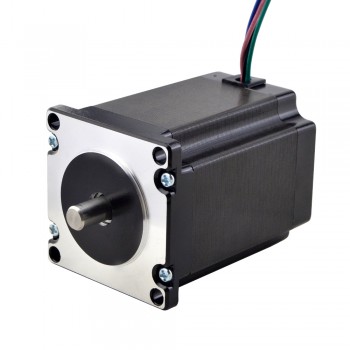

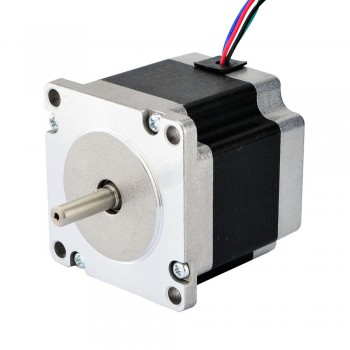

Nema 23 Stepper Motor Bipolar 3Nm (425oz.in) 3.5A 57x57x114mm 4 Wires CNC Stepper Motor

This bipolar Nema 23 stepper motor with step angle 1.8deg and size 57x57x114mm. It has 4 wires, each phase draws 3.5A, with holding torque 3.0Nm (425oz.in).

Electrical Specification

Manufacturer Part Number: 23HS45-3504S

Motor Type: Bipolar Stepper

Step Angle: 1.8 deg

Holding Torque: 3.0Nm(425oz.in)

Rated Current/phase: 3.5A

Voltage: 4.2V

Phase Resistance: 1.2ohms

Inductance: 5.0mH ± 20%(1KHz)

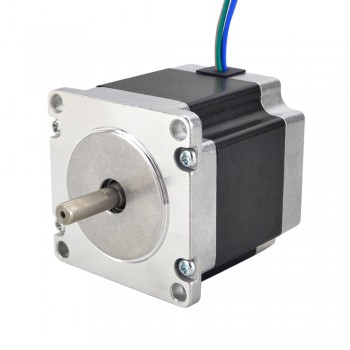

Physical Specification

Frame Size: 57 x 57mm

Body Length: 113mm

Shaft Diameter: Φ10mm

Shaft Length: 24mm

D-cut Length: 20mm

Number of Leads: 4

Lead Length: 400mm

Weight: 1.8kg

Connection

|

A+

|

A-

|

B+

|

B-

|

|

Black

|

Green

|

Red

|

Blue

|

Resources

Full Datasheet: 23HS45-3504S.pdf

Torque Curver: 23HS45-3504S Torque Curve.pdf

Wholesale stepper motors and wholesale stepper motor drivers online with guaranteed quality and competitive price at Oyostepper.com!

| Electrical Specification | |

|---|---|

| Bipolar/Unipolar | Bipolar |

| Holding Torque (Ncm) | 300 |

| Holding Torque (oz.in) | 425 |

| Inductance(mH) | 5 |

| Phase Resistance(ohm) | 1.2 |

| Rated Current (A) | 3.5 |

| Step Angle(°) | 1.8 |

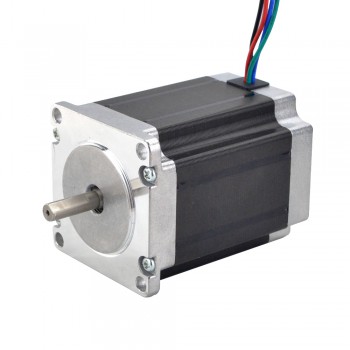

| Physical Specification | |

| Body Length(mm) | 113 |

| Frame Size(mm) | 57x57 |

| Single Shaft/Dual Shaft | Single Shaft |

| Shaft Type | D-Cut |

| Shaft Diameter(mm) | 10 |

| Shaft Length(mm) | 24 |

| No. of Lead | 4 |

| Lead Length(mm) | 400 |

| Weight(g) | 1600 |

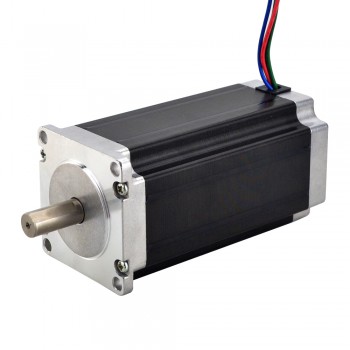

- Connectors: Molex, Harwin, Tyco/AMP, JST etc.

- Lead wires & cables: Special lengths, Protective hose

- Shaft: Round, D-Cut, Cross drilled, Key-Way, Thread or Hollow

- Winding: Resistance, Inductance, Rated Current, etc.

RAFAEL OSORIO – 19 May 2017

Very good kit!! Thank you

Phillip Vogel – 28 Nov 2016

I've been doing control systems for a long, long time and I got this kit to help me model a system in my shop. I'm pretty impressed. There's not much to say about it, it just works. On the plus side, the step, direction and enable inputs are optically isolated, which is good for system reliability and for flexibility. They bring out both sides (cathode and anode) of the optos, so if your signal polarity is backwards, you can just reverse the wires. There is plenty of flexibility in step sizes from one to 51,200 pulses per step. The output current regulation is adjustable from 0.75 to 4.5 amps, The terminal strips are pluggable so you can replace the drive easily, if need be. One thing I would have liked is separate terminal blocks for the motor, motor power, logic power and control signals. It would make things slightly easier on assembly. I'm pretty sure that these terminals are stackable, so just swapping the plugs out for smaller ones should be simple.

- Tag:

- 4 Wires